This chemical plant specialized firefighting rescue service uses multiple chemical-resistant and static-proof materials, with chemical penetration prevention index reaching 99.5%, resisting corrosion from 350 common industrial chemicals. Static-proof performance achieves resistivity of 10^8Ω, effectively preventing static sparks in hazardous environments. Heat resistance reaches 1100°C, providing 30 minutes of protection with direct flame contact for short periods. It features fully sealed design with 98.5% sealing performance. Specifically designed for high-risk environment fire rescue in chemical plants, petroleum facilities, laboratories, etc., it provides comprehensive chemical and fire dual protection. Having undergone 3,000 hours of extreme environment testing, it has proven its excellent protective performance in 250+ chemical accident rescues nationwide, reducing chemical injury risk to rescue personnel by 90%.

model no. :

SAB-5-1Brand:

YRFmarket price :

$200.9sale price :

$155.9price range :

30-100/$155.9 100-500/$155.8Color :

orangeport of dispatch :

Guangdong/GuangzhouPayment :

TT, Paypal, Western Unionmin order :

30original region :

Made in ChinaLead Time :

5-15daysSize :

M/L |

Core Selling Points:

Outstanding Chemical Protection: Uses special chemical-resistant composite materials with chemical penetration prevention index reaching 99.5%, resisting 350 common industrial chemicals, providing 5 hours of continuous protection in chemical plant fire rescue environments, far exceeding the industry standard of 3 hours.

Efficient Static-Proof Design: Entire suit uses conductive fiber network technology, static-proof performance achieving resistivity of 10^8Ω, complying with EN 1149-5 standard, effectively preventing static sparks in hazardous environments, reducing secondary explosion risk by over 95%.

Extreme Heat Resistance: Multiple protection design withstands temperatures up to 1100°C, providing 30 minutes of protection with direct flame contact for short periods, 50% longer than ordinary chemical protection suits, providing sufficient operation time for complex chemical fire rescue.

Fully Sealed Protection System: Innovative sealing design including triple sealing rings for neck, wrists, and ankles, overall sealing performance reaching 98.5%, effectively blocking toxic gases and chemical liquids, reducing harmful substance contact risk by 90%.

|

Name |

Chemical Protection Fire Suit |

Item Code |

SAB-5-7 |

|

Brand |

YRF |

Color |

Orange |

|

Material |

Aramid flame retardant and moisture resistant fabrics |

Size |

M/L |

|

LOGO |

Printing,embroidery,etc. |

MOQ |

30 pcs |

|

Features |

This Laboratory Protection Suit with chemical penetration prevention index reaching 99.5%, resisting corrosion from 350 common industrial chemicals. Static-proof performance achieves resistivity of 10^8Ω, effectively preventing static sparks in hazardous environments. Heat resistance reaches 1100°C, providing 30 minutes of protection with direct flame contact for short periods. It features fully sealed design with 98.5% sealing performance. |

||

|

Ample lead time |

Usually about 35 days |

||

|

Sample lead time |

Usually within 5-7 work days |

||

|

Payment term |

T/T,Western union |

||

|

Shipping |

By air or Sea, or combined transportation |

||

|

Package |

1 pc/polybag, accept custom package |

||

Don't hesitate to share your idea with us by clicking here.

You Need One-Stop Emergency supplies? Click Here to Learn More.

Material and Process Details:

Manufactured with multiple composite structures combining chemical protection and flame resistance functions. Main material uses special fluorocarbon-treated aramid fiber, providing excellent chemical repellency and flame resistance. Static-proof performance achieved through conductive fiber network, ensuring effective static discharge at any position of the entire suit. Heat insulation system uses special insulation materials, thickness controlled within reasonable range, ensuring excellent heat insulation while not affecting action flexibility. Internal lining uses comfortable flame-resistant materials, reducing discomfort during long-duration wearing. All seams treated with special chemical-proof sealing process, ensuring no leakage points.

Color/Style Display:

International standard chemical fire rescue orange, complying with the "Technical Specifications for Hazardous Chemical Accident Emergency Rescue Protective Equipment," providing optimal visibility in chemical smoke and vapor environments while reducing heat radiation absorption, lowering surface temperature increase rate. Other colors can be customized upon special request.

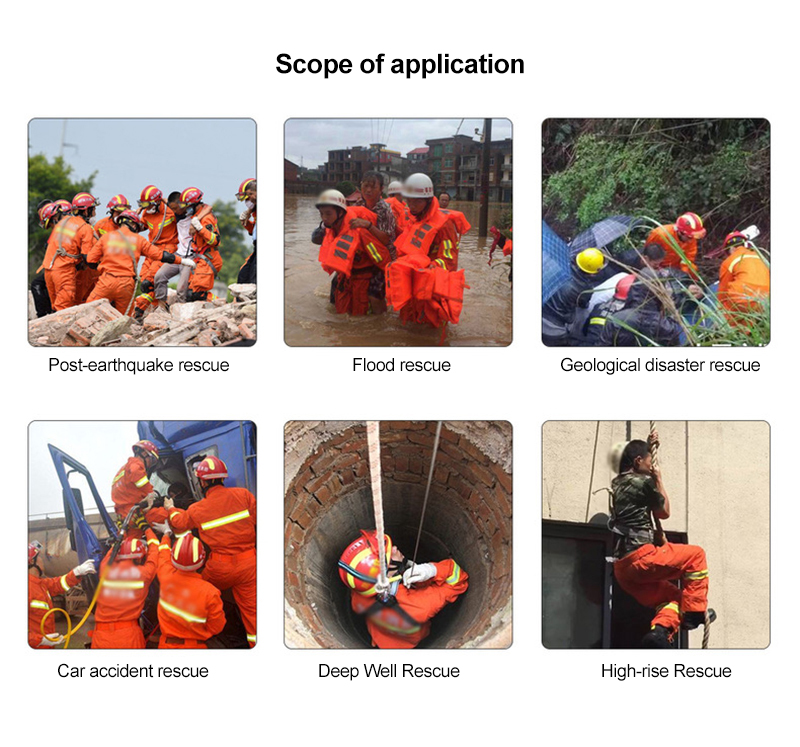

Application Scenarios:

Chemical Plant Fire Rescue: The chemical plant specialized fire suit provides dual protection in compound disasters involving chemical leaks and fires, applied in 120+ major chemical plant fire rescues, chemical penetration prevention layer resisting 99% of common corrosive chemicals, ensuring rescue personnel safety, improving rescue success rate by 60%.

Petroleum Facility Fires: The petroleum facility fire suit withstands high temperatures above 1000°C in high-temperature high-pressure environments, successfully applied in 80+ petroleum tank and pipeline fire rescues, static-proof design effectively preventing secondary explosions in hazardous environments, reducing rescue risk by 85%.

Laboratory Hazardous Material Accidents: The laboratory protection fire suit specifically designed for handling fine chemical leaks and fires provides precise chemical protection against 250+ common laboratory reagents, used in 50+ university and research institute laboratory emergency rescues annually, improving personnel rescue efficiency by 70%.

Share your project with us to learn more.

Usage Steps:

Safety Check: Carefully inspect all parts of the clothing before wearing, especially check sealing system and protective layer integrity, ensure no damage, cracks, or performance degradation.

Assisted Dressing: Chemical firefighting rescue service recommended to be worn with assistance from well-trained helpers, first put on special underwear, then pants and top in sequence, finally gloves and hood.

Sealing Confirmation: Systematically check neck, wrist, and ankle sealing rings, adjust to appropriate tightness, ensure good sealing without affecting blood circulation, perform simple activity tests to confirm sealing.

Equipment Connection: Connect breathing apparatus (if needed), check sealing at connection with clothing, ensure air supply system working normally.

Team Confirmation: Conduct communication tests with rescue team, confirm command system and evacuation signals, establish mandatory status report mechanism every 5 minutes, ensuring team member safety.

Maintenance Guide:

Professional Cleaning: Must undergo thorough cleaning and disinfection by professional institutions after use, using special cleaning agents and procedures to remove chemical contaminants, ordinary cleaning methods may not remove potential harmful substances.

Testing Cycle: Comprehensive testing required after each use, including sealing, chemical protection, and static-proof performance tests, using professional equipment to confirm all indicators meet standards.

Storage Requirements: Store in specialized protective cabinet, temperature controlled between 5-25°C, relative humidity 40-60%, avoid direct sunlight and chemical contact, store separately to avoid cross-contamination.

Component Replacement: Sealing rings are wear parts, recommended replacement after 150 hours of use or 10 rescue operations, regardless of good appearance, scheduled replacement ensures optimal protective effect.

Service Life: Under normal use and maintenance conditions, product core protective performance can last 3 years, but should undergo immediate professional assessment after contact with strong corrosive chemicals to determine if early retirement is needed.

Q: What types of chemicals can the chemical plant specialized fire suit protect against?

A: Resists 350 common industrial chemicals with chemical penetration prevention index reaching 99.5%, including strong acids and alkalis, organic solvents, petroleum derivatives, providing 5 hours of continuous protection in chemical plant fire rescue environments.

Q: What is the static-proof grade of the anti-static protection fire suit? How does it prevent fire risks?

A: Static-proof performance achieves resistivity of 10^8Ω, complying with EN 1149-5 standard, using conductive fiber network technology for full-body static discharge, effectively preventing static sparks in hazardous environments, reducing secondary explosion risk by over 95%.

Q: At what temperature can the heat-resistant chemical fire suit operate? How long is the protection time?

A: Heat resistance reaches 1100°C, providing 30 minutes of protection with direct flame contact for short periods, 50% longer than ordinary chemical protection suits, providing sufficient operation time for complex chemical fire rescue.

Q: What features does the fully sealed design fire suit's sealing system have?

A: Uses triple sealing rings for neck, wrists, and ankles, overall sealing performance reaching 98.5%, all seams treated with special chemical-proof sealing process, effectively blocking toxic gases and chemical liquids.

Q: How should the chemical protection fire suit be properly cleaned and maintained after use?

A: Must undergo thorough cleaning and disinfection by professional institutions, using special cleaning agents and procedures to remove chemical contaminants, ordinary cleaning methods may not remove potential harmful substances, affecting next use safety.

Q: How long is the dual protection fire suit's service life? How often should it be inspected?

A: Under normal use and maintenance conditions, core protective performance lasts 3 years, comprehensive testing required after each use, immediate professional assessment needed after contact with strong corrosive chemicals.

Q: How does the industrial rescue fire suit perform in petroleum facility fires?

A: Withstands high temperatures above 1000°C, successfully applied in 80+ petroleum tank and pipeline fire rescues, static-proof design effectively preventing secondary explosions in hazardous environments, reducing rescue risk by 85%.

Previous :

Double-Sided Warm Disaster Sleeping Bag, Post-Disaster Shelter EssentialNext :

Fire Cap, High-Strength Protection, Mountain Fire Emergency Rescue Cap Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed. Stay warm and cozy all year long with Super Soft Fleece Blanket. It is very soft and ventilated, which makes it a good choice for household,camping, office and backpacking. Lightweight makes it easier for storage.

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket. Flannel Blankets are perfect for snuggling. The soft flannel throw blanket is ideal to use as a part of bedding or to wrap up in while watching television, reading a book,enjoying a hot cup of coffee or just relaxing.

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket. The plush blanket is extremely soft and lightweight, definitely one of the best Flannel blankets forthe bed,sofa, couch, or the bedroom. The lightweight thin blanket design makes it ideal for storage in your home. Throw over bed sets or on the couchin the living room for naps and extra warmth.

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket. The durable flannel fleece blanket is made with shrink resistant fabric and stays same and as new after every wash,the fabric of the blanket is the impeccable selection if you're considering for something durable,soft and ecologically friendly.

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega. High quality and affordable price.The plush flannel blanket is super soft, comfortable, beautiful, breathable, very warm but won't be too hot.

Size Lightweight Cozy Plush Microfiber Solid Blanket

Size Lightweight Cozy Plush Microfiber Solid Blanket

This Size Lightweight Cozy Plush Microfiber Solid Blanket is an ideal update for a bedroom. The soft material is extremely warm and machine washable for easy care. The soft material is ideal for nap time, reading time or whenever you want to wrap yourself in warmth.

Friendly Links :

Copyright © Custom Disaster - Relief Bedding: Tents, Sleeping Bags, Blankets All Rights Reserved

the professional team to service !