This injurious medical bag is specially designed for medical institutions to safely handle sharp waste, adopting advanced anti-puncture technology, with puncture resistance up to 450g, effectively preventing occupational exposure risks caused by needles, blades, and other sharp objects penetration. The standard red design complies with GB 19217-2011 medical waste classification regulations, with conspicuous sharp object warning symbols facilitating correct classification. Made of high-strength composite material, with a thickness of 0.09mm, 80% thicker than ordinary medical waste bags, featuring excellent tear resistance and impact resistance. The bottom adopts innovative "X-shaped" heat-sealing process, with corner strength improved by 60%, solving the problem of sharp objects easily piercing bag corners. Passed ASTM F1342 puncture testing and ISO 13485 certification, meeting the Medical Waste Management Regulations requirements. Particularly suitable for operating rooms, injection rooms, dental departments, and other places generating large amounts of sharp waste, it is a professional solution for medical institutions to prevent occupational exposure.

model no. :

WB-01-8Brand:

YRFmarket price :

$2sale price :

$1.45price range :

30-100/$1.45 100-500/$1.39Color :

Redport of dispatch :

Guangdong/GuangzhouPayment :

TT, Paypal, Western Unionmin order :

30original region :

Made in ChinaLead Time :

5-15daysSize :

14.7*19 in |

Core Selling Points

Excellent Anti-Puncture Performance: Adopts innovative multi-layer composite protective structure, with puncture resistance up to 450g, passing ASTM F1342 puncture testing, 125% higher than ordinary medical waste bags, effectively preventing injection needles, surgical blades, and other sharp objects from penetrating the bag, reducing the risk of occupational exposure for medical staff by over 90%.

Standard Red Warning: Adopts standard red (PMS 185C) complying with GB 19217-2011 regulations, with color difference controlled within ΔE≤2 range, conspicuousness improved by 50%, printed with internationally recognized sharp object hazard symbols and "Injurious Waste" warning text, facilitating quick identification by medical staff, ensuring classification accuracy.

High-Strength Thickened Material: Made of medical-grade high-density composite material, with a thickness of 0.09mm, 80% thicker than ordinary medical waste bags, tensile strength ≥40MPa, elongation at break ≥650%, providing excellent mechanical strength and physical barrier, ensuring safe packaging of sharp waste.

Innovative Heat-Sealing Process: The bottom adopts patented "X-shaped" heat-sealing technology, with a heat-sealing width of 15mm, heat-sealing strength of 25N/15mm, corner strength improved by 60%, thoroughly solving the industry pain point of traditional medical waste bags easily being pierced from the bottom corners when loading sharp objects.

Comprehensive Safety Certification: Passed ISO 13485 medical device quality management system certification, ASTM F1342 puncture testing, and JIS Z1707 sharp object penetration testing, fully complying with the Medical Waste Management Regulations and WHO medical waste management guidelines, providing compliance assurance for medical institutions.

|

Name |

Medical Sharp Object Anti-Penetration Garbage Bag |

Item Code |

WB-01-8 |

|

Brand |

YRF |

Thikcness |

0.09mm |

|

Size |

14.7*19 in /Or customize |

Material |

HDPE |

|

Color |

Red/White/yellow/etc. |

MOQ |

30 pcs |

|

Features |

(1) Puncture resistance; |

||

|

Ample lead time |

Usually about 35 days |

||

|

Sample lead time |

Usually within 5-7 work days |

||

|

Payment term |

T/T,Western union |

||

|

Shipping |

By air or Sea, or combined transportation |

||

|

Package |

(1)100pcs packing in one bag |

||

Don't hesitate to share your idea with us by clicking here.

You Need One-Stop Emergency supplies? Click Here to Learn More.

Material and Process Details

Made of medical-grade high-density composite material, with main components being specially modified high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE), adding special puncture-resistant enhancers. The material has a density of 0.96g/cm³, with thickness precisely controlled at 0.09±0.005mm, far exceeding the minimum thickness of 0.05mm required by the national standard GB 19217-2011, providing more reliable physical protection.

The product is manufactured using advanced four-layer co-extrusion composite technology, forming a multi-layer protective structure: the outermost layer is high-strength HDPE, adding anti-UV agents and red masterbatch, ensuring bright and lasting color; the second layer is a special nano anti-puncture layer, adding inorganic nanoparticles, significantly enhancing puncture resistance; the third layer is a high-toughness reinforcement layer, providing excellent tear resistance and impact resistance; the innermost layer is modified LLDPE, providing good extensibility and sealing properties. The four layers work together, forming an all-around protective barrier.

The bag bottom adopts innovative "X-shaped" heat-sealing process, adding X-shaped cross reinforcement structure on the basis of traditional straight-line heat-sealing, with a heat-sealing width of 15mm, heat-sealing temperature precisely controlled at 195±3°C, pressure 0.7MPa, forming an extremely firm bottom structure. The bag bottom corners are specially reinforced, using double-layer heat-sealing reinforcement, solving the weakest link of traditional medical waste bags that are most easily pierced when loading sharp objects.

The sharp object warning symbols are printed using special wear-resistant ink, complying with FDA food-grade safety standards, with strong printing adhesion, not easily fading or peeling off, remaining clear and identifiable after 10,000 friction tests. The symbol design complies with ergonomic principles, with high visual recognition, clearly visible even in low-light environments.

Each batch of products undergoes strict quality control testing, including puncture testing, heat-sealing strength testing, tensile performance testing, and drop testing, ensuring stable and reliable product performance, meeting the stringent requirements for handling medical sharp waste. Particularly for puncture testing, standard medical needles (21G) are tested under 450g pressure, ensuring the product can effectively prevent sharp objects penetration in actual use.

Application Scenarios

Hospital Operating Room: Each operation generates a large amount of sharp waste, such as surgical blades, suture needles, etc., the anti-puncture design of the injurious medical bag ensures these sharp objects do not penetrate the bag, the red warning design reminds operating room staff to handle with care, ensuring a safe working environment.

Injection Room/Infusion Room: Routinely handles a large number of injection needles, these sharp objects are the main risk source for occupational exposure of medical staff, red specialized bags with 450g puncture resistance serve as a secondary protective layer for sharps containers, providing additional safety assurance for medical staff, reducing the risk of needle stick injuries.

Dental Clinic: Generates numerous sharp instrument waste, such as dental needles, drill bits, etc., these small sharp objects have strong penetration, ordinary garbage bags are easily pierced, while professional injurious medical bags provide reliable protection, helping clinics standardize medical waste management.

Laboratory Department Laboratory: Handles various glass test tubes, slides, and other fragile sharp objects, these items have high puncture risk when broken with sharp edges, anti-puncture design red specialized bags effectively prevent sharp objects penetration, ensuring laboratory personnel safety.

Medical Waste Transfer Process: Medical waste needs to be moved multiple times from the point of generation to final disposal, high-strength anti-puncture design and innovative heat-sealing process ensure no easy piercing by internal sharp objects during frequent moving, preventing sharp waste leakage causing environmental pollution and safety risks.

Usage Steps

Preparation Work: Confirm using a red injurious medical bag, check if the bag body is intact, if the sharp object warning symbols are clear.

Correct Unfolding: Gently shake the medical bag to completely unfold it, being careful not to use excessive force causing static electricity or bag damage.

Appropriate Installation: Place the medical bag on a dedicated sharp waste container, fold the bag opening outward covering the container edge by about 15cm, ensuring stability without slipping.

Safe Disposal: Sharp waste (such as needles, blades) should first be placed in dedicated sharps containers, then the sharps containers placed in red specialized bags, forming double protection; note to control the amount not exceeding 2/3 of the bag's capacity, reserving enough space for safe sealing.

Check Contents: Before sealing, confirm all sharp objects are safely packaged in sharps containers, not directly contacting the bag, reducing puncture risk.

Safe Sealing: Carefully lift the bag opening, avoiding touching internal waste, use high-strength ties to tightly seal at a position 8cm from the bag opening, ensuring firm sealing.

Double Sealing: To increase the safety factor, it is recommended to tie again at a position 5cm above the first seal, forming a double sealing structure, especially when handling high-risk sharp waste.

Information Marking: Mark department, date, waste type, responsible person, and other information in the designated area of the bag, facilitating traceability management.

Safe Transfer: Grab the upper safe area of the bag (at least 10cm away from the seal) for transfer, avoid the bag being close to the body, handle with care, avoiding violent shaking and collisions, preventing internal sharp objects from piercing the bag.

Maintenance Guide

Storage Conditions: Store in a dry, well-ventilated, and shaded environment, temperature controlled between 0-35°C, relative humidity not exceeding 70%, avoiding direct sunlight and high-temperature environments, preventing material aging.

Protection Measures: The storage area should be away from heat sources, fire sources, and chemicals, avoiding contact with sharp objects, preferably equipped with dedicated medical waste bag storage racks or containers, reducing the risk of accidental damage.

Shelf Life: Under recommended storage conditions, unopened products have a shelf life of 36 months, and opened products should be used within 18 months, exceeding the limit may affect anti-puncture performance and material toughness.

Batch Management: Medical institutions should establish an injurious medical bag usage registration system, recording batch numbers and usage situations, implementing a first-in-first-out principle, ensuring product use within the validity period.

Emergency Plan: Develop a sharp waste leakage emergency handling plan, equip spare injurious medical bags, sharps forceps, disinfectants, and other emergency supplies, regularly train medical staff, ensuring prompt and effective handling in case of accidents.

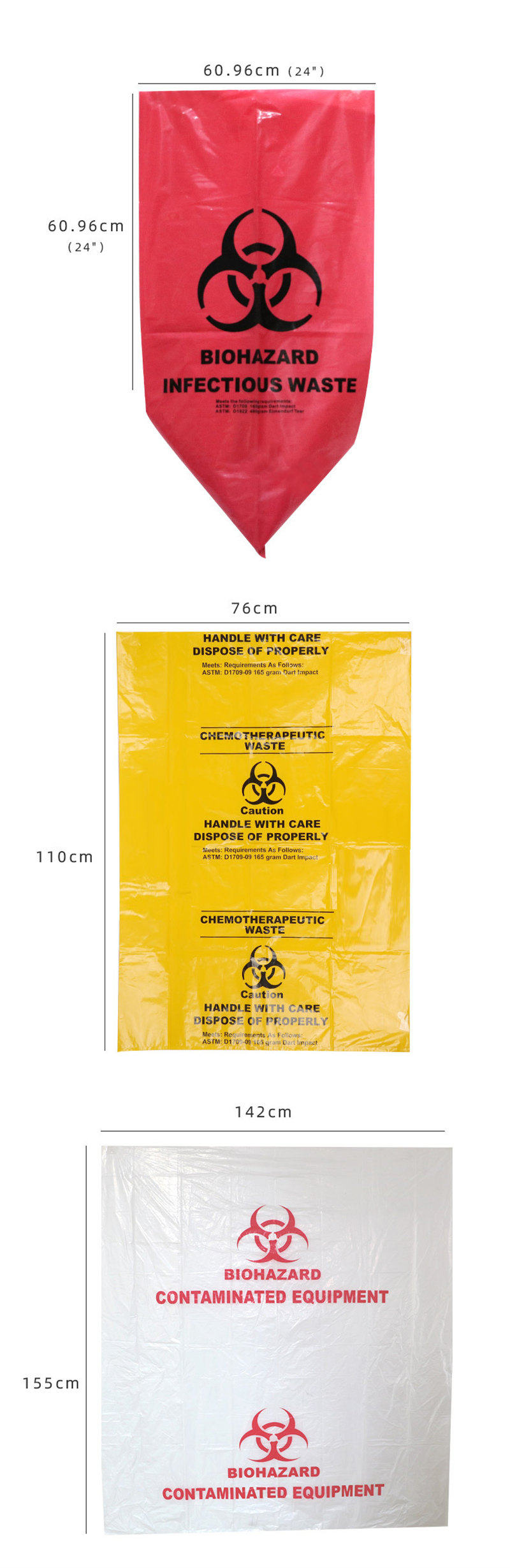

Color/Style Display

Standard Red Version: Standard red (PMS 185C) complying with GB 19217-2011 regulations, printed with internationally recognized sharp object hazard symbols and "Injurious Waste" warning text, the most basic style commonly used in hospitals, suitable for collecting various sharp waste.

Red Thickened Enhanced Version: Further increases thickness to 0.1mm on the basis of the standard version, with puncture resistance enhanced to 500g, specially designed for high-risk areas such as operating rooms, dental departments, etc., providing higher-level safety assurance.

Red Transparent Bottom Version: Innovative design, maintaining red warning effect while using transparent design at the bottom, facilitating medical staff observation of contents, confirming if sharp objects are completely packaged, particularly suitable for special medical scenarios requiring content visibility.

Share your project with us to learn more.

Question: What does a puncture resistance of 450g mean?

Answer: A puncture resistance of 450g means that under standard testing conditions (such as ASTM F1342 testing), a force of 450g is required for a standard test needle to penetrate the bag material. This value is 125% higher than ordinary medical waste bags (typically around 200g), effectively resisting puncture from most medical sharp objects, such as 21G injection needles, small surgical blades, broken glass, etc., significantly reducing the risk of occupational exposure for medical staff during handling of sharp waste.

Question: Why must injurious medical bags be red?

Answer: According to GB 19217-2011 "Regulations on Standards and Warning Signs for Medical Waste Specialized Packaging and Containers" and the Medical Waste Classification Catalog, red is the internationally recognized warning color for injurious waste, used to collect discarded items that can puncture or cut the human body. The conspicuous red helps medical staff quickly identify bags containing sharp waste, increasing vigilance, handling more carefully, reducing the risk of accidental injury, while also facilitating medical waste classification management and tracking.

Question: What are the advantages of four-layer co-extrusion composite technology?

Answer: Four-layer co-extrusion composite technology forms a multi-layer protective structure, with each layer playing a different role: the outermost high-strength HDPE layer provides basic strength and color; the second nano anti-puncture layer specifically targets sharp object penetration; the third high-toughness reinforcement layer prevents tearing and impact; the innermost modified LLDPE layer provides extensibility and sealing properties. This multi-layer structure provides more comprehensive protection than single-layer materials, even if one layer is damaged, other layers still provide protection, greatly improving overall safety.

Question: How does the "X-shaped" heat-sealing process solve the problem of corner penetration?

Answer: Traditional medical waste bags use straight-line heat-sealing, forming stress concentration points at corners, easily pierced by sharp objects. The "X-shaped" heat-sealing process adds X-shaped cross reinforcement structure on the basis of traditional straight-line heat-sealing, and reinforces the corners with double-layer heat-sealing, with a heat-sealing width of 15mm, heat-sealing strength of 25N/15mm, corner strength improved by 60%. This innovative design disperses stress, eliminates weak points, thoroughly solving the problem of sharp waste bags most easily pierced at bottom corners.

Question: Can sharp objects be directly placed in injurious medical bags?

Answer: No. Although this product has excellent anti-puncture performance, according to the Medical Waste Management Regulations and medical waste handling best practices, sharp waste (such as needles, blades) should first be placed in dedicated sharps containers, then the sharps containers placed in red specialized bags, forming double protection, minimizing puncture risks. The injurious medical bag serves as a second line of defense, further enhancing the safety factor, not substituting sharps containers.

Question: Is this product suitable for high-temperature disinfection or sterilization?

Answer: This product's material can withstand temperatures below 85°C for a short time, suitable for routine surface disinfection treatment, but high-temperature sterilization (such as autoclave sterilization at 121°C) is not recommended, as this may cause material deformation or performance degradation. If high-risk sharp waste needs to be inactivated, it is recommended to disinfect in dedicated sharps containers, or use specially designed medical waste bags that can withstand high temperatures.

Question: How can medical institutions verify the anti-puncture performance of injurious medical bags?

Answer: Verification can be done through the following methods: ①Check if the product has ASTM F1342 or JIS Z1707 testing certification; ②Check if the thickness reaches the claimed value (0.09mm); ③Observe if it has a four-layer composite structure (can be observed from the cut edge); ④Perform a simple puncture test (try to pierce with a discarded injection needle using moderate pressure); ⑤Perform a water test to verify leak-proof performance; ⑥Request third-party testing reports and samples from suppliers for evaluation.

Previous :

Camouflage Post-Disaster Tent, 100km/h Wind, 220cm High for Storm Aid - YRFNext :

Medical Garbage Professional Bag, Anti-Cross-Infection, Roll Type Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed. Stay warm and cozy all year long with Super Soft Fleece Blanket. It is very soft and ventilated, which makes it a good choice for household,camping, office and backpacking. Lightweight makes it easier for storage.

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket. Flannel Blankets are perfect for snuggling. The soft flannel throw blanket is ideal to use as a part of bedding or to wrap up in while watching television, reading a book,enjoying a hot cup of coffee or just relaxing.

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket. The plush blanket is extremely soft and lightweight, definitely one of the best Flannel blankets forthe bed,sofa, couch, or the bedroom. The lightweight thin blanket design makes it ideal for storage in your home. Throw over bed sets or on the couchin the living room for naps and extra warmth.

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket. The durable flannel fleece blanket is made with shrink resistant fabric and stays same and as new after every wash,the fabric of the blanket is the impeccable selection if you're considering for something durable,soft and ecologically friendly.

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega. High quality and affordable price.The plush flannel blanket is super soft, comfortable, beautiful, breathable, very warm but won't be too hot.

Size Lightweight Cozy Plush Microfiber Solid Blanket

Size Lightweight Cozy Plush Microfiber Solid Blanket

This Size Lightweight Cozy Plush Microfiber Solid Blanket is an ideal update for a bedroom. The soft material is extremely warm and machine washable for easy care. The soft material is ideal for nap time, reading time or whenever you want to wrap yourself in warmth.

Friendly Links :

Copyright © Custom Disaster - Relief Bedding: Tents, Sleeping Bags, Blankets All Rights Reserved

the professional team to service !