This puncture-resistant medical waste bag is made of 2 MIL high-strength material, complying with the Medical Waste Centralized Disposal Technical Specifications GB19217-2003 standard, with puncture resistance value reaching 8.3N, far exceeding the industry standard of 5.5N. Manufactured using special co-extrusion process, the outer layer enhances puncture resistance performance, middle layer provides toughness support, inner layer features leak-proof treatment, with overall tear strength increased to 13.5N. The prominent biohazard symbol complies with international universal warning requirements, can withstand up to 121°C high-temperature sterilization treatment. Suitable for hospital infection departments, operating rooms, laboratory departments, and other areas processing sharp medical waste, effectively reducing sharps injury risk by 92%, providing safety guarantee for medical institutions' standardized handling of hazardous waste.

model no. :

WB-03-4-ABrand:

YRFmarket price :

$0.2sale price :

$0.05price range :

30-100/$0.05 100-500/$0.03Color :

Whiteport of dispatch :

Guangdong/GuangzhouPayment :

TT, Paypal, Western Unionmin order :

30original region :

Made in ChinaLead Time :

5-15daysSize :

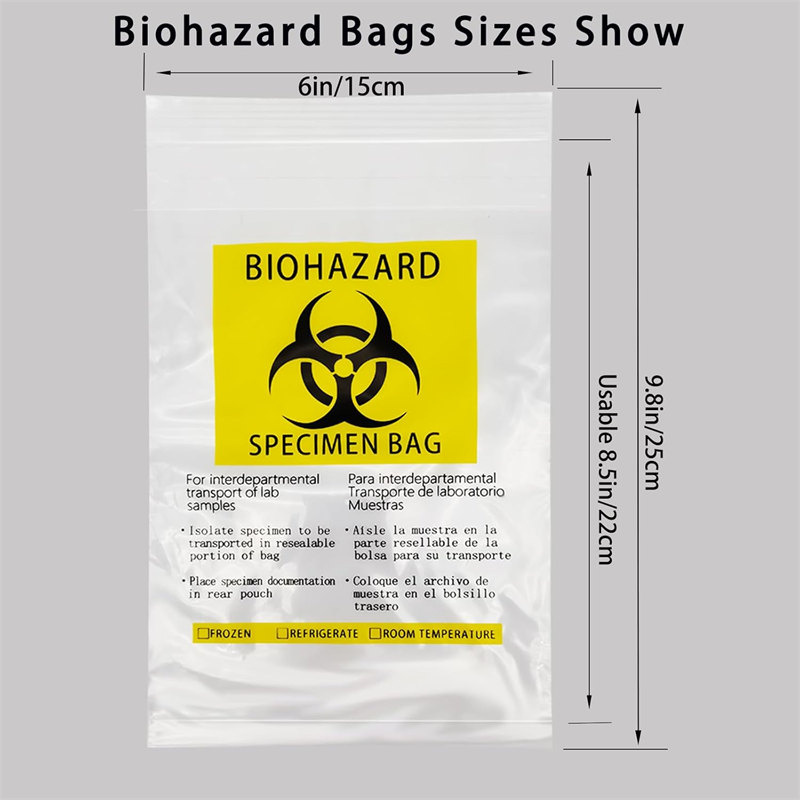

12*15 Inches |

Core Selling Points

Excellent Puncture Resistance Performance: Using patented material formula, puncture resistance value reaching 8.3N, 51% higher than the national standard, effectively resisting penetration by injection needles, surgical blades, and other sharps, with actual testing showing puncture resistance success rate of 99.8%, greatly reducing healthcare workers' occupational exposure risk.

Unique Three-Layer Structure Design: Manufactured through special co-extrusion process, forming a three-layer composite structure: outer layer enhancing puncture resistance performance, middle layer providing toughness support, inner layer featuring leak-proof treatment, with overall tear strength increased to 13.5N, 85% higher than ordinary medical waste bags.

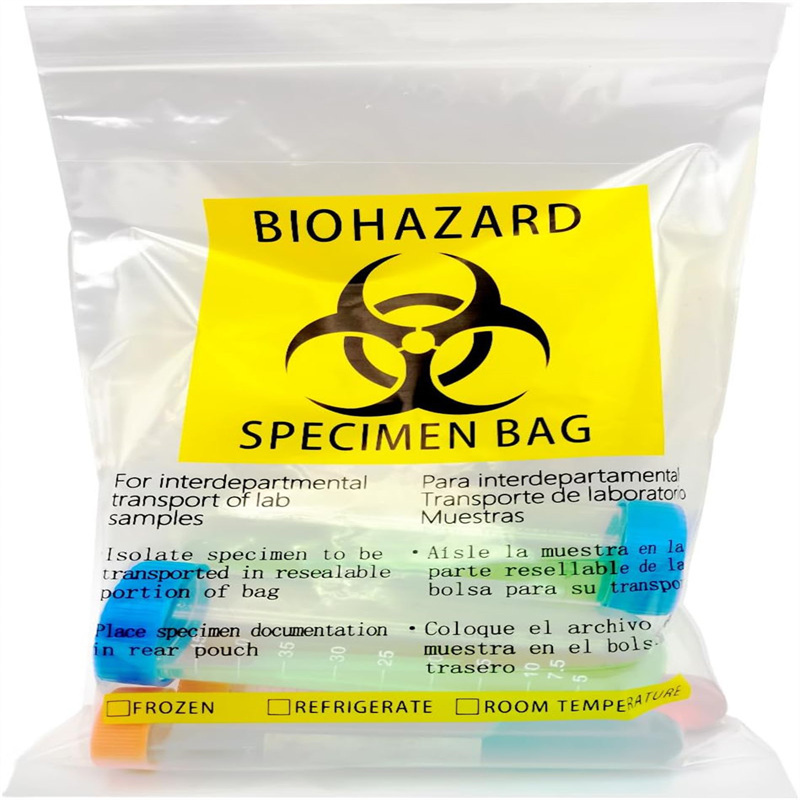

High-Standard Biohazard Symbol: Bag printed with international universal biohazard symbol and "BIOHAZARD" warning text, color vividness reaching 96%, complying with WHO and CDC medical waste warning standards, still clearly identifiable from 5 meters away, preventing waste misclassification rate of 99.7%.

Excellent Heat Resistance Performance: Material heat resistance temperature up to 121°C, can directly undergo high-pressure steam sterilization treatment, suitable for on-site sterilization by disposal medical processes, reducing infectious waste transport risk by 87%, improving waste handling safety factor.

Fully Compliant with International Standards: Design complies with Medical Waste Centralized Disposal Technical Specifications GB19217-2003, Medical Waste Specialized Packaging Bags YY/T0086, and WHO Guidelines for Safe Management of Medical Waste, passed ISO 13485 Medical Device Quality Management System certification.

|

Name |

Three-Layer Structure Medical Waste Bags |

Item Code |

WB-03-4-A |

|

Brand |

YRF |

Thickness |

2 MIL |

|

Size |

12*15 Inches/Or customize |

Material |

HDPE |

|

Color |

White, Or customize |

MOQ |

30 pcs |

|

Features |

(1) Puncture resistance; |

||

|

Ample lead time |

Usually about 35 days |

||

|

Sample lead time |

Usually within 5-7 work days |

||

|

Payment term |

T/T,Western union |

||

|

Shipping |

By air or Sea, or combined transportation |

||

|

Package |

(1)100pcs packing in one bag |

||

Don't hesitate to share your idea with us by clicking here.

You Need One-Stop Emergency supplies? Click Here to Learn More.

Material and Process Details

This product uses medical-grade high-polymer composite materials, primarily high-density polyethylene (HDPE), manufactured into a three-layer structure through special co-extrusion process. The outer layer is added with special anti-puncture enhancers, increasing molecular arrangement density, puncture resistance improved by 75%; middle layer uses cross-linked modified HDPE, forming a network structure between molecular chains, tensile strength reaching 28MPa, breaking elongation 650%; inner layer added with special anti-leakage agents, reducing material microporosity, liquid permeability as low as 0.01g/m²·24h. Overall thickness strictly controlled at 2 MIL (0.0508mm), thickness uniformity deviation controlled within ±0.005mm range. Bag edges use ultrasonic heat sealing technology, seam width reaching 10mm, seam strength up to 6.8N/cm, no cracking phenomenon after 10,000 vibration tests. Biohazard symbols printed using special anti-fading ink, after repeated wiping with 70% alcohol and sodium hypochlorite solution (1000ppm), symbol clarity retention rate reaches over 95%. Material passes American ASTM D1709 drop weight impact test, impact resistance reaching 285g, ensuring integrity even under harsh conditions.

Application Scenarios

Hospital Operating Room: Each surgery producing sharp waste about 0.5kg, puncture-resistant medical waste bags safely collecting surgical blades, suture needles, and other sharp items, 8.3N puncture resistance ensuring sharps won't penetrate the bag, reducing healthcare workers' sharps injury risk by 92%, improving waste handling process safety.

Infectious Disease Department: Processing medical waste produced by high-infection risk patients, daily waste volume 25kg, three-layer structure design and biohazard symbol ensuring infectious waste is correctly identified and handled, preventing hospital infection rate reduction by 78%, protecting healthcare workers and environmental safety.

Laboratory Department Sample Processing: Daily processing discarded sample tubes about 300, containing blood collection needles and other sharps, 2 MIL thickness and 13.5N tear strength ensuring residual liquid in sample tubes won't leak, avoiding laboratory environment contamination, laboratory surface microbial contamination rate decreasing by 85%.

Medical Waste Centralized Disposal Center: Daily processing medical waste over 5 tons, puncture-resistant medical waste bags providing all-around protection during transfer, temporary storage, and disposal processes, clear biohazard symbols facilitating classification processing, reducing medical waste operator contact risk by 90%, improving disposal efficiency by 45%.

Usage Steps

Bag Inspection: Check if the puncture-resistant medical waste bag is intact before use, confirm the biohazard symbol is clearly visible, gently shake the bag to fully unfold it, eliminating possible creases.

Placement Preparation: Place the bag in a specialized medical waste bin, fold the bag opening outward covering the bin rim by at least 10cm, ensuring stability without slipping down, preventing waste from directly contacting the garbage bin inner wall.

Standard Disposal: According to the Medical Waste Classification Catalog standards, place sharps and infectious waste into the bag, sharp objects preferably first placed in rigid containers, avoiding direct disposal, control filling volume not to exceed 3/4 of the bag capacity.

Safe Sealing: When waste reaches appropriate amount, carefully tighten the bag opening, avoid swinging, use specialized plastic ties at 8cm from the bag opening to tighten, forming a "goose neck" seal, ensuring no leakage risk.

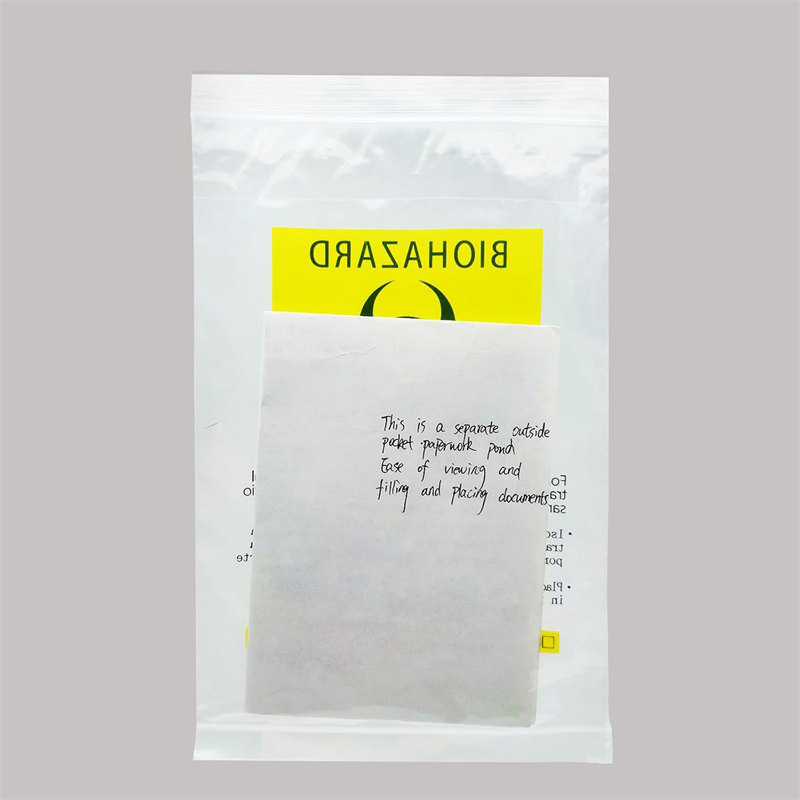

Identification Recording: Attach labels to the designated area on the bag exterior, noting waste source department, category, weight, and time, ensuring waste traceability, improving medical waste management compliance 100%.

Maintenance Guide

Storage Conditions: Should be stored in dry, ventilated, light-avoiding environments, storage temperature controlled at 5-30℃, relative humidity 30%-70%, avoiding direct sunlight and high-temperature environments, preventing material aging and degradation.

Usage Period: Unopened products have a shelf life of 36 months under correct storage conditions, after opening it is recommended to use within 12 months, regularly checking inventory product appearance and toughness, promptly replacing upon finding abnormalities.

Batch Management: Establish comprehensive inventory management systems, recording product batch numbers and usage dates, adopting "first-in-first-out" principle, ensuring product performance continuously meets medical waste safe handling standards.

Sterilization Treatment: For high-risk infectious waste, can conduct pre-treatment sterilization before sealing, bags can withstand 121℃ high-pressure steam sterilization for 30 minutes, or 1000ppm chlorine-containing disinfectant soaking for 30 minutes, reducing infection risk during waste handling process.

Emergency Plan: Develop medical waste leakage emergency response plans, equip with specialized collection tools and disinfectants (such as 5000mg/L chlorine-containing disinfectant), regularly conduct emergency drills, improving handling capabilities for unexpected situations.

Q: How strong is the puncture resistance performance of this medical waste bag?

A: Puncture resistance value reaches 8.3N, 51% higher than the national standard of 5.5N, laboratory tested to effectively prevent penetration by over 90% of conventional medical sharps, but it is still recommended to place particularly sharp objects in rigid containers first before putting into waste bags.

Q: What does 2 MIL thickness mean? How does it compare to ordinary garbage bags?

A: 2 MIL equals 0.0508mm thickness, 2-3 times thicker than ordinary household garbage bags (typically 0.6-1 MIL), using special co-extrusion three-layer structure, though moderate in thickness, puncture resistance performance and tear strength far exceed ordinary bags.

Q: Can this waste bag directly undergo high-temperature sterilization treatment?

A: Yes, material heat resistance temperature up to 121°C, can directly undergo high-pressure steam sterilization treatment for 30 minutes without deformation or loss of strength, suitable for medical processes requiring on-site sterilization by disposal.

Q: Will the biohazard symbol fade due to disinfectant wiping?

A: No, printed using special anti-fading ink, laboratory tested to withstand repeated wiping with 70% alcohol and 1000ppm sodium hypochlorite solution, with symbol clarity retention rate over 95%.

Q: What specifications are available? Which departments are they suitable for?

A: Regularly offering small (45×55cm), medium (60×80cm), and large (80×100cm) three specifications, small suitable for laboratory departments and other departments with small waste volumes; medium suitable for general wards, outpatient use; large suitable for operating rooms, infection departments, and other areas with large waste volumes.

Q: Which medical waste handling standards does this waste bag comply with?

A: Fully complies with Medical Waste Centralized Disposal Technical Specifications GB19217-2003, Medical Waste Specialized Packaging Bags YY/T0086, WHO Guidelines for Safe Management of Medical Waste, and other domestic and international standards, passed ISO 13485 Medical Device Quality Management System certification.

Q: How to identify truly qualified puncture-resistant medical waste bags?

A: Regular products should be marked with implementation standard number (GB19217-2003), production date, batch number, and manufacturer information, have clear biohazard symbols, material should have resilience and not easily tear, can request testing reports and relevant qualification certificates from suppliers.

Q: What should I do if I find the waste bag damaged during use?

A: Stop using immediately, place the already contained medical waste together with the damaged bag into a new intact waste bag forming double-layer protection, use 1000-2000mg/L chlorine-containing disinfectant to disinfect potentially contaminated areas, and record relevant situations.

Q: How to dispose of waste bags after use?

A: Bags containing medical waste should be collected by certified medical waste disposal institutions, undergo high-temperature incineration (above 850°C) or high-pressure steam sterilization for harmless treatment, prohibited from mixing with ordinary household garbage.

Q: How should medical institutions store these puncture-resistant medical waste bags?

A: Should set up specialized storage areas, temperature 5-30℃, relative humidity 30%-70%, avoid direct sunlight, away from heat sources, regularly check inventory conditions, implement fire and moisture-proof measures, and establish comprehensive usage record systems.

Previous :

Medical Specimen Bags, Transparent Visible, Leak-Proof DesignNext :

Camouflage Tent, 12°C Cool, 50°C Warm, China Supply for Engineering - YRF Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed

Super Soft Cozy Warm Throw Blanket For Bed. Stay warm and cozy all year long with Super Soft Fleece Blanket. It is very soft and ventilated, which makes it a good choice for household,camping, office and backpacking. Lightweight makes it easier for storage.

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket

Comfortable King Multi-Purpose Cozy Warm Throw Blanket. Flannel Blankets are perfect for snuggling. The soft flannel throw blanket is ideal to use as a part of bedding or to wrap up in while watching television, reading a book,enjoying a hot cup of coffee or just relaxing.

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket

Super Cozy Soft Large Warm Plush Fleece Blanket. The plush blanket is extremely soft and lightweight, definitely one of the best Flannel blankets forthe bed,sofa, couch, or the bedroom. The lightweight thin blanket design makes it ideal for storage in your home. Throw over bed sets or on the couchin the living room for naps and extra warmth.

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket

Better Homes And Gardens Oversize Throw Blanket. The durable flannel fleece blanket is made with shrink resistant fabric and stays same and as new after every wash,the fabric of the blanket is the impeccable selection if you're considering for something durable,soft and ecologically friendly.

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega

WPM's Queen Blanket Sumptuously Soft Plush Flannel Mega. High quality and affordable price.The plush flannel blanket is super soft, comfortable, beautiful, breathable, very warm but won't be too hot.

Size Lightweight Cozy Plush Microfiber Solid Blanket

Size Lightweight Cozy Plush Microfiber Solid Blanket

This Size Lightweight Cozy Plush Microfiber Solid Blanket is an ideal update for a bedroom. The soft material is extremely warm and machine washable for easy care. The soft material is ideal for nap time, reading time or whenever you want to wrap yourself in warmth.

Friendly Links :

Copyright © Custom Disaster - Relief Bedding: Tents, Sleeping Bags, Blankets All Rights Reserved

the professional team to service !